Refine Product List

Laser Accessories

Detector Bracket, Universal, Sliding, Cut and Fill & Elevation Rod Product #UB-1 $79.00

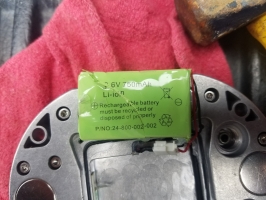

GeoMax CHARGER Rechargable battery pack for Zone Lasers Li-Ion Product #835242 $45.00

GeoMax CHARGER Rechargable battery pack for Zone Lasers Li-Ion Product #835242 $45.00 GeoMax Rechargable battery pack for Zone Lasers Li-Ion Product #835243 $236.00

GeoMax Rechargable battery pack for Zone Lasers Li-Ion Product #835243 $236.00 LaserLine GR1000 Lenker type, 10 Foot Direct Cut, Fill & Elevation Reading Laser Rod Product #GR1000 $185.00

LaserLine GR1000 Lenker type, 10 Foot Direct Cut, Fill & Elevation Reading Laser Rod Product #GR1000 $185.00 LaserLine Target Template (2 Pack) for Quad 1000 Laser Product #4001-0010 $45.00

LaserLine Target Template (2 Pack) for Quad 1000 Laser Product #4001-0010 $45.00 Nedo Jumbo 13' Elevating Aluminum Tripod Product #210540-185 $1,250.00

Nedo Jumbo 13' Elevating Aluminum Tripod Product #210540-185 $1,250.00 Bracket for Laser level Detector receiver, Cut and Fill Rod Trimble Product #B1-T $71.00

Bracket for Laser level Detector receiver, Cut and Fill Rod Trimble Product #B1-T $71.00 LaserLine Trivet Floor Mount for Quad 1000 Laser Product #4200-0000 $245.00

LaserLine Trivet Floor Mount for Quad 1000 Laser Product #4200-0000 $245.00 R9 Proshot Laser Level detector Receiver with Clamp Product #R9 $189.00

R9 Proshot Laser Level detector Receiver with Clamp Product #R9 $189.00 GeoMax ZRB35 Basic Laser Receiver Product #ZRB35 $180.00

GeoMax ZRB35 Basic Laser Receiver Product #ZRB35 $180.00 Heavy Duty Elevating Nedo Aluminum Tripod, 40-116" Product #210678-185 $395.00

Heavy Duty Elevating Nedo Aluminum Tripod, 40-116" Product #210678-185 $395.00 AGL MR360RA Machine Laser Receiver and Cab display Product #6009255 $2,149.00

AGL MR360RA Machine Laser Receiver and Cab display Product #6009255 $2,149.00 RC-60 REMOTE CONTROLLER Product #313670002 $359.00

RC-60 REMOTE CONTROLLER Product #313670002 $359.00 LS-80X Laser Sensor Product #1046259-01 $289.00

LS-80X Laser Sensor Product #1046259-01 $289.00 Topcon Holder 6, bracket only for LS-80L Product #312890112 $70.00

Topcon Holder 6, bracket only for LS-80L Product #312890112 $70.00 ZRP 105 Geomax Pro Receiver Large Pickup area with Bracket Product #835247 $300.00

ZRP 105 Geomax Pro Receiver Large Pickup area with Bracket Product #835247 $300.00 AGL MR240 Laser Machine Control Receiver Product #16281 $675.00

AGL MR240 Laser Machine Control Receiver Product #16281 $675.00 Laser Target for DZ and other high rise Vertical plumb laser Product #DZ0012 $24.00

Laser Target for DZ and other high rise Vertical plumb laser Product #DZ0012 $24.00 David White Heavy-Duty Laser Column Clamp (4852-16) Product #4852-16 $410.00

David White Heavy-Duty Laser Column Clamp (4852-16) Product #4852-16 $410.00 Geomax Laser Detector Receiver with Rod Bracket Product #869174 $184.00

Geomax Laser Detector Receiver with Rod Bracket Product #869174 $184.00 Seco or David White Laser Column Clamp (4852-15) Product #485215 $285.00

Seco or David White Laser Column Clamp (4852-15) Product #485215 $285.00 Topcon Laser detector receiver for Machine Control, Excavator, Back Hoe Product #LSB-10 $695.00

Topcon Laser detector receiver for Machine Control, Excavator, Back Hoe Product #LSB-10 $695.00 Batterboard clamp, Seco Column Clamp, Product #4852-14 $154.00

Batterboard clamp, Seco Column Clamp, Product #4852-14 $154.00 Pro Shot NiMh Rechargeable Laser Battery Kit for L4.7 and AS2 Product #500250M $67.00

Pro Shot NiMh Rechargeable Laser Battery Kit for L4.7 and AS2 Product #500250M $67.00Topcon Holder, alkaline battery, RL-H4C Topcon laser Product #313680702 $95.00

B-Storm, Laserline Cut and Fill bracket, clamp, for ATI Storm Product #B-Storm $74.00

B-Storm, Laserline Cut and Fill bracket, clamp, for ATI Storm Product #B-Storm $74.00 Ls-100D Topcon Digital Laser receiver, instant cut and fill Product #LS-100D $340.00

Ls-100D Topcon Digital Laser receiver, instant cut and fill Product #LS-100D $340.00 Nedo 1 meter Extension for Industrial tripod Product #660020 $165.00

Nedo 1 meter Extension for Industrial tripod Product #660020 $165.00 Topcon LS-100D Laser Digital Receiver with Bracket Product #LS-100D $340.00

Topcon LS-100D Laser Digital Receiver with Bracket Product #LS-100D $340.00 AGL Replacment Battery for AGL EZ Dig Pro sensor 7.5 mAH Product #755533 $95.00

AGL Replacment Battery for AGL EZ Dig Pro sensor 7.5 mAH Product #755533 $95.00